Why one small Scottish island supplies every Olympic curling stone

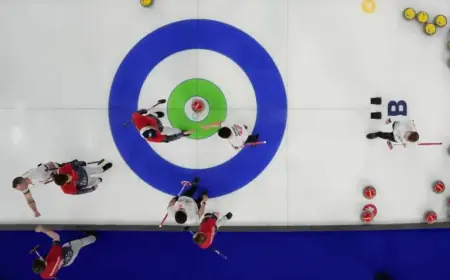

Feb. 14, 2026 ET — When curling matches at the Winter Olympics hinge on inches, the provenance of the stones matters. Every elite curling stone used at the Games is crafted from granite quarried on a tiny, windswept island off Scotland’s west coast and finished by a small, specialist factory that has refined the material for generations.

From volcanic plug to Olympic ice: the island that supplies the stones

About 10 miles off the Turnberry coast sits Aisla Craig, an uninhabited volcanic plug that rises more than 11 stories from the Firth of Clyde. Geologically ancient — its origins trace back roughly 600 million years — the island holds two distinct granites prized by stone makers. The harder, blue-honed granite forms the stone’s running band, while a Common Green granite, resistant to heat transfer and splintering, composes the bulk of the body. That combination is said to produce a durable, predictable running surface that elite curlers trust.

The human scale: a small factory with a global reach

Roughly a 45-minute drive north of Turnberry, a compact workshop employs about 50 people to turn the island’s granite into competition-grade stones. The factory operates on a modest schedule and focuses on craftsmanship rather than mass production. For the Olympic program, the maker established an exclusive supply relationship in the mid-2000s, consolidating the production of stones for the world’s top competitions under one specialist roof.

How the stone’s make-up affects curling scoring

At its simplest, curling scoring depends on which team’s stones are closest to the center of the target — known as the house — after each end. But that simplicity masks the fine margins athletes contend with. A stone’s running band must interact consistently with the ice: too much variability and curlers can’t reliably place weight or line, which increases the chance of missed scoring opportunities. The Aisla Craig granites are valued because the running surface wears evenly and resists micro-fractures, helping stones travel true and predictably. That predictable behavior is a foundation for precise shot-making and, by extension, accurate scoring.

Why one source rather than many?

Manufacturers and governing bodies prioritize uniformity. When every competition stone has the same response to sweeping, speed changes and ice temperature variation, teams can expect consistent behavior and judges can better ensure fairness. The island’s granite is rare; its physical properties aren’t easily replicated elsewhere. Years of experience with the rock, coupled with a concentrated production process, have created an industry standard that organizers rely on for elite competition.

Craftsmanship, history and a sport that rewards precision

The relationship between a single island and global curling highlights how tradition and technical needs intersect. The factory’s craftsmen have spent roughly 175 years refining their approach to shaping and finishing the rock, honing tolerances that matter at the highest levels. In play, a thrower pushes a roughly 40-pound stone down a 150-foot sheet of ice toward the house while teammates sweep to manage friction and trajectory. Those elements — human skill, ice science and the stone’s material properties — come together to determine scoring outcomes measured in inches.

As curling continues to draw attention on the Olympic stage, the link between an isolated Scottish outcrop and scoreboard drama remains a vivid reminder that, in some sports, the smallest details can decide the biggest moments.