3D Printing Advances: Soft Robots Now Move Precisely as Designed

Recent advancements in 3D printing have led to significant breakthroughs in the field of soft robotics. Engineers at Harvard University have developed a novel technique that allows soft robots to move in highly predictable ways when inflated. This innovative approach embeds shape-morphing capabilities directly into the printed materials, simplifying the design process traditionally fraught with challenges.

Key Innovations in 3D Printing for Soft Robotics

Soft robots are primarily constructed from flexible and biocompatible materials. Their applications range from surgical tools to industrial manipulators. However, controlling the movement of these robots has often been a complex task. Traditional manufacturing methods, which involve molds and layered casting, slow down customization and make it labor-intensive.

Revolutionary Printing Technique

The new method developed by the research team, including graduate student Jackson Wilt and former postdoctoral researcher Natalie Larson, streamlines the manufacturing process. It employs rotational multimaterial 3D printing, utilizing a single nozzle to print multiple materials simultaneously. This technique eliminates the need for molds and allows for rapid design modifications.

Process Details

- The team printed flexible filaments with a tough outer shell made of polyurethane.

- A gel-like core, which is removable, was incorporated to create hollow channels within the filament.

- Once printed, the outer shell solidified while the inner gel was washed away, forming pneumatic pathways.

These channels facilitate precise bending and twisting when air is pumped into them. The researchers can control the movement by adjusting the nozzle’s rotation speed and print parameters.

Applications and Demonstrations

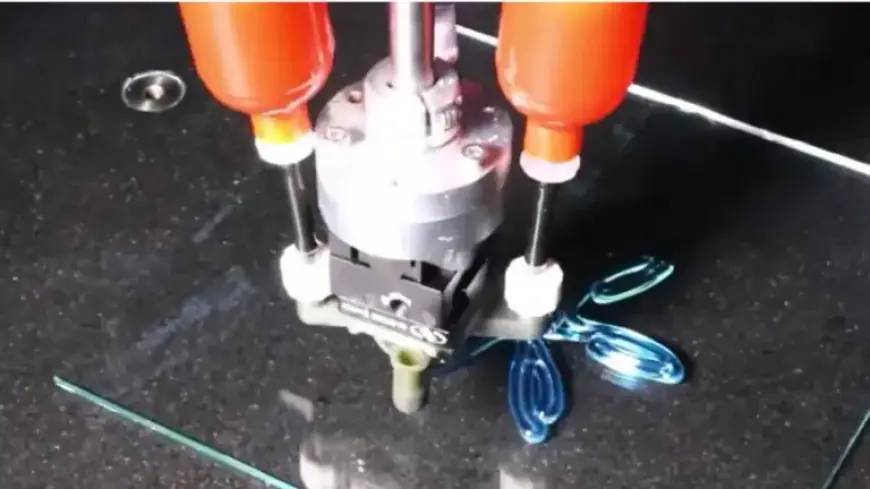

The research demonstrated its capabilities by printing a flower-like actuator that opens and curls when inflated. Additionally, they created a hand-shaped gripper with articulated joints, showcasing how complex movements can be achieved through a single printing process. These advancements signify a potential shift in soft robot designs, embedding functionality directly into the printed structures.

Implications for Future Robotics

The innovative technique opens new avenues for developing soft robots for various applications, including surgical and assistive devices. With the ability to rapidly customize motions, it could revolutionize manufacturing tools capable of handling delicate objects. As noted by Natalie Larson, who currently serves as an assistant professor at Stanford University, this approach redefines how engineers conceptualize soft robotics.

The study detailing these findings was published in the journal Advanced Materials, highlighting the significance of this breakthrough in 3D printing technology.