Inside Google’s Exclusive Pixel Hardware Labs: A Rare Glimpse

Inside Google’s Pixel Hardware Labs in Taipei, Taiwan, the company conducts extensive research and development to refine its popular Pixel smartphones. This facility, the largest outside the United States, features over 50 specialized labs focused on various aspects of hardware testing.

Exploring Google’s Exclusive Pixel Hardware Labs

A recent tour granted a select group of journalists a rare look into five of these high-tech labs. This exclusive visit underscored the meticulous processes that ensure the reliability and functionality of Pixel devices used by millions.

Durability Testing at the Reliability Lab

The first stop was the Pixel Reliability Lab, where Google performs rigorous stress tests on its devices. Notable tests include:

- Water Resistance: Testing begins with the IPX4 water resistance assessment. A rotating turntable sprays the phone from various angles for ten minutes, ensuring it can withstand everyday exposures.

- Sit Test: This unique test gauges the phone’s robustness when sat upon, simulating pressure from a pocket.

- Drop Tests: Different materials are dropped from varying heights to analyze impact resistance on the display and frame.

- Fold Test: Specifically for the Pixel 10 Pro Fold, this test assesses the hinge and display durability with 200,000 open-close cycles.

- Tumble Test: A simulation mimics the conditions of a handbag, exposing the device to various everyday items to evaluate its toughness.

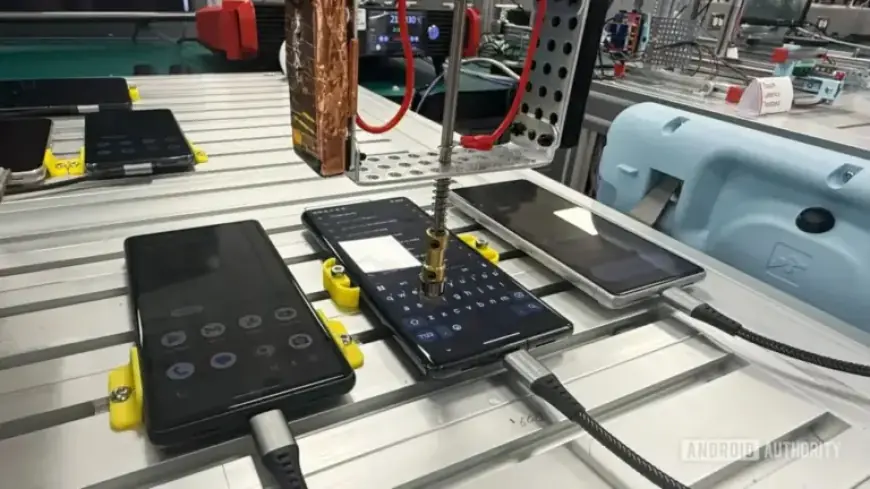

Advanced Robotic Connectivity Testing

Next, the robotic connectivity lab showcased advanced automation in testing Pixel sensors. Robotic arms swiftly assess:

- Touch latency

- Temperature sensors

- Light sensors

- Proximity sensors

Each robotic system has been customized by Google to maximize efficiency in testing, demonstrating how crucial these sensors are to user experience.

Audio Quality Evaluation

The audio lab reinforces the importance of sound quality in Pixel devices. Here, Google focuses on:

- Real-time Voice Translate feature

- Audio Zoom functionality, which enhances sound capture while minimizing background noise

- Call quality assessments, ensuring clear voice transmission even in noisy environments

The lab features anechoic chambers designed to eliminate all external noise, providing a precise testing environment for audio evaluations.

Design Innovations in the Design Lab

The final destination was the design lab, the birthplace of Pixel products. This area is pivotal for:

- Material selection and product planning

- Development of complex components such as the gearless hinge in the Pixel 10 Pro Fold

- Testing materials’ durability under extreme stress conditions

- Innovations in thermal management technologies

Products are meticulously designed to endure years of use while remaining functional and stylish.

The Takeaway from Pixel Labs

This deep dive into Google’s Pixel Hardware Labs reveals the extensive research, testing, and engineering behind each device. While other smartphone manufacturers also conduct rigorous testing, Google’s unique approach and custom methodologies stand out. This inside look provided valuable insights into the challenges and innovations that shape Pixel smartphones before they reach consumers.