Ultrathin Electronic Coating’s Hidden Leak Baffles Researchers for a Decade

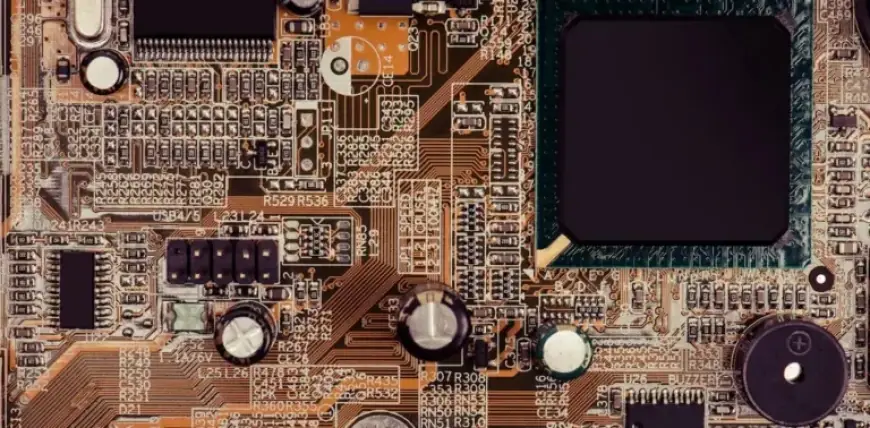

Researchers have encountered challenges with ultrathin electronic coatings, particularly those designed to insulate electrical currents. These coatings play a crucial role in the performance and efficiency of modern electronics. Their ability to effectively store and control charge is vital in devices ranging from smartphones to advanced AI systems.

Understanding Dielectric Materials

In the field of electronics, insulating materials, known as dielectrics, are essential components. They separate conductors in devices like capacitors and transistors. These layers are crucial for controlling the flow of electricity.

Key features of dielectrics include:

- Thiness: Modern dielectric layers can be just a few nanometers thick.

- Functionality: They store charge and enable the operation of capacitors and transistors.

- Material Properties: The performance of these materials is often determined by their dielectric constant (k).

The Quest for Thinner Insulators

As devices demand more compact designs, the push for thinner dielectrics has intensified. However, there is a critical balance to maintain. Thinning materials can lead to electrical leakage through quantum tunneling, particularly with traditional silicon dioxide at approximately 1.2 nanometers. This leakage diminishes the effectiveness of the device.

To counter this, engineers have explored materials with a higher dielectric constant. For instance, switching from silicon dioxide (k of 3.9) to aluminum oxide (k of 8) allows for thicker layers without sacrificing charge storage.

Breakthrough and Its Setback

In 2010, a groundbreaking claim was made by researchers indicating the development of a nanolaminate material with a staggering dielectric constant nearing 1,000. This structure alternated layers of aluminum oxide and titanium oxide to achieve remarkable properties.

However, recent studies uncovered that the reported properties were misleading, stemming from significant leakage within the material. This instability rendered it impractical as a reliable insulator.

Identifying the Leak Source

Further investigation revealed that the initial layers of aluminum oxide lacked sufficient aluminum content, allowing electrons to escape. The manufacturing process, specifically atomic layer deposition, contributed to this inadequacy.

By replacing the oxygen source of aluminum oxide from water to ozone during production, researchers effectively eliminated leakage pathways. This alteration allowed the material to function as a true insulator, even at diminutive thicknesses.

Implications for Future Technology

The advancements in these ultrathin coatings represent a significant stride towards enhancing the reliability of electronic components. Understanding the chemistry involved in creating these materials could lead to further innovations in the design of capacitors and transistors.

As researchers continue to explore the boundaries of material science, the journey toward perfecting insulating layers will undoubtedly reshape the future of electronic devices.