Musk Diverts Tesla Investors with Optimus Robot Hype

Tesla has announced ambitious plans to pivot its manufacturing focus towards humanoid robots, which could redefine its future. The company is grappling with an 11 percent decline in automotive revenue in the fourth quarter of 2025 and aims to invest $20 billion in capital expenditures this year. This significant investment is primarily targeted at enhancing manufacturing and computational infrastructure.

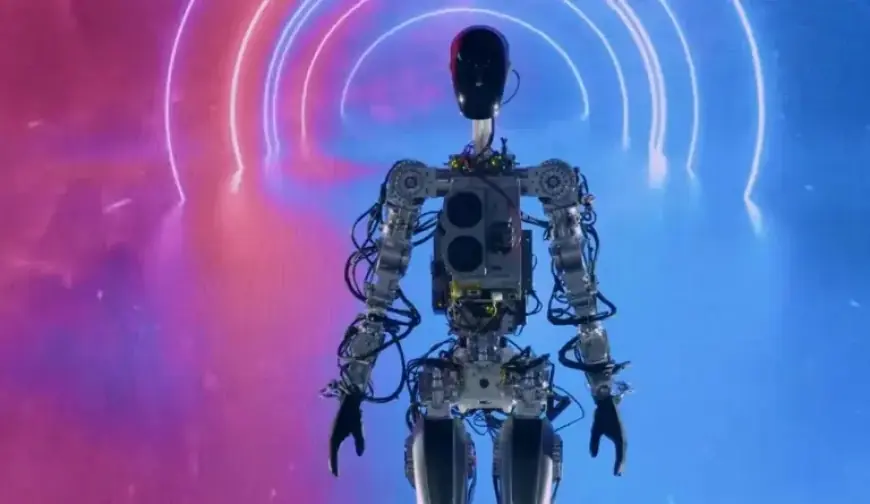

Tesla’s Vision for the Optimus Robot

The centerpiece of Tesla’s new strategy is the development of the Optimus robot. Described as a “general-purpose, bi-pedal humanoid robot,” Optimus is designed to tackle tasks deemed unsafe, repetitive, or mundane. Tesla aims to achieve a production capacity of one million units annually from its Fremont, California facility, which is currently transitioning from producing the Tesla S and X models, both of which were discontinued in the second quarter of 2026.

Production Goals and Challenges

Elon Musk expressed confidence during Tesla’s Q4 2025 earnings call. “I’m confident that we’ll get to a million units a year in Fremont of Optimus 3,” he stated. The manufacturing cost for each Optimus robot is targeted at $20,000. However, despite these ambitious goals, skepticism remains regarding the actual utility of these robots.

- Optimus robots are still in the early stages of development and currently do not perform significant work.

- The current iterations of the robot are mainly used for research and development activities.

- Musk noted that meaningful production volumes are not expected until the end of 2026.

Industry Perspective on Humanoid Robots

The robotics industry remains cautious about the commercial viability of humanoid robots. Companies like Boston Dynamics and Hyundai have set modest production goals of approximately 30,000 humanoid robots annually, primarily for warehouse functions. At the recent Humanoids Summit in Mountain View, California, experts voiced concerns about deploying humanoid robots outside controlled environments.

Technical and Practical Barriers

A report by McKinsey titled “Humanoid robots: Crossing the chasm from concept to commercial reality” highlights significant barriers to the widespread adoption of humanoid robots. Key challenges include:

- Safety concerns surrounding free-roaming robots.

- Limited battery life when not connected to power sources.

- Insufficient dexterity and mobility for complex tasks.

- The high cost of development and production.

Experts like Lei Yang, CEO of IntBot, acknowledge rapid advances in AI and hardware but emphasize the need for safe, reliable humanoid robots. Many existing demonstrations often rely on scripted actions rather than true autonomy.

The Future of Humanoid Robots

Despite the challenges, there remains optimism about the future of humanoid robots. Dale Walsh, VP of strategy and innovation at Roboworx, notes that while specific tasks can now be performed by humanoid robots, true general-purpose functionality is still not present in the market. Veteran roboticists are wary, with some predicting that it may take decades to see robots capable of matching human capabilities on a larger scale.

As Tesla continues to push the boundaries of robotics, the journey towards practical, humanoid robots may involve navigating numerous technical, economic, and social hurdles.